Services

Coating Surface Preparation Specialist

.

At Freelander Tech Sdn Bhd we have good experience in the industry and we abide with all atmospheric and structural specification for each project.

Surface preparation is the most crucial aspect of industrial coating projects. Various methods are used to prepare a surface by removing product build up, dirt, oil, corrosion scale, old coatings, fragile materials and contaminants from the surface.

We provide a comprehensive industrial surface preparation and surface coating service in Brunei Darussalam. We use specialized equipment and safe techniques for surface preparation and coating depending on customer specification.

In order to prove our deliverance of uncompromised quality, our BGAS and NACE certified inspectors takes all measures to check that the painting specifications meet the standards of quality control and higher most quality.

Find out more about what we can do with Surface Preparation work

Freelander Tech Sdn Bhd is the successful pioneer in introducing Vapor Abrasive Blasting (Wet Abrasive Blasting) in Brunei Darussalam. Vapor Abrasive Blasting removes coatings, contaminants, corrosion and residues from hard surfaces. Its similar to dry sand blasting, except that the blast media is moistened prior impacting the surface.

The main advantage of vapor abrasive blasting over sand blasting is that it reduces dust, allowing for operators to work in a wide range of environments with minimal setup and cleanup costs. It results in a cleaner, more consistent finished, ready to coat with no embedded particles or clinging dust.

Dry abrasive blasting, generally referred to as sandblasting, is a process by which ageing paint can be removed to condition the under coated material (referred to as the substrate) ready for the application of new paint. This is achieved by propelling an abrasive material at high pressure on to the painted surface.

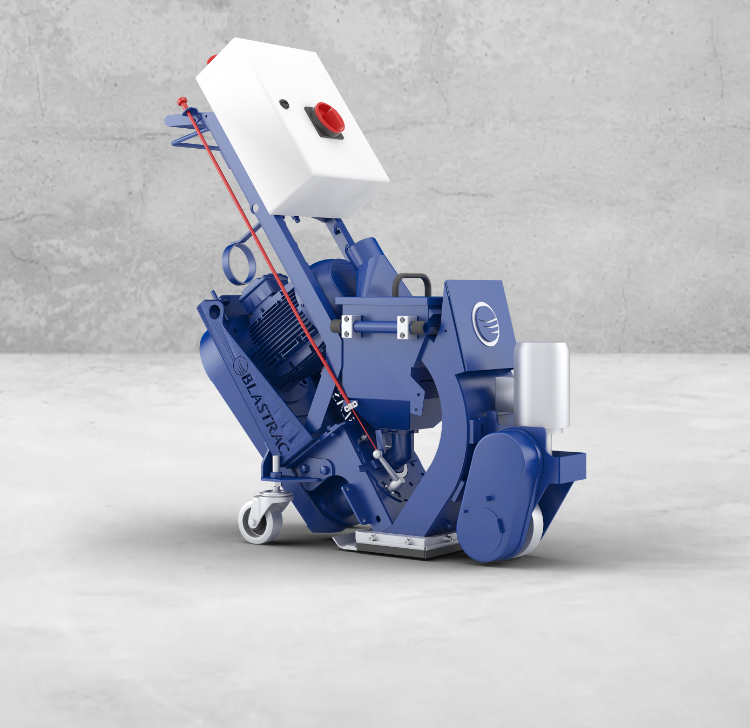

Blastrac closed circuit media shot blasting machines throw a large amount of steel abrasive media by centrifugal force at the surface. After the steel abrasive hits the surface, the shot blaster recycles the media. Dust and contaminants are removed by an air wash separator and are removed to a dedicated Blastrac dust collector. This makes the process almost dust-free in operation.

Shot blasting with steel shot is the most environmentally friendly abrasive blasting method there is, because there is no use of chemical products and no waste of valuable drinking water. The video below shows the shot blasting process perfectly.

The world’s only hand power tools that can “sandblast”. The patented technology removes corrosion and coatings quickly and thoroughly. Bristle blaster is a great alternative to sandblasting. At the same time, the Bristle Blaster® and MBX® create surface preparation grades comparable with Sa2½ (SSPC-SP 10/NACE No. 2) to Sa3 (SSPC-SP 5/NACE No. 1) and roughness levels of up to 120 µm Rz.

We are a trusted, high quality applicator of specialised coatings in oil & gas and petrochemical We offer over various standard coatings, though new projects, tighter specifications, differing priorities and environmental issues mean we often have to respond with customized solutions. We specialize BSP DEP specification surface coating with TAMAP approved paint suppliers and providing technical expertise.

Our Registered Partner & Certification